CASE STUDY

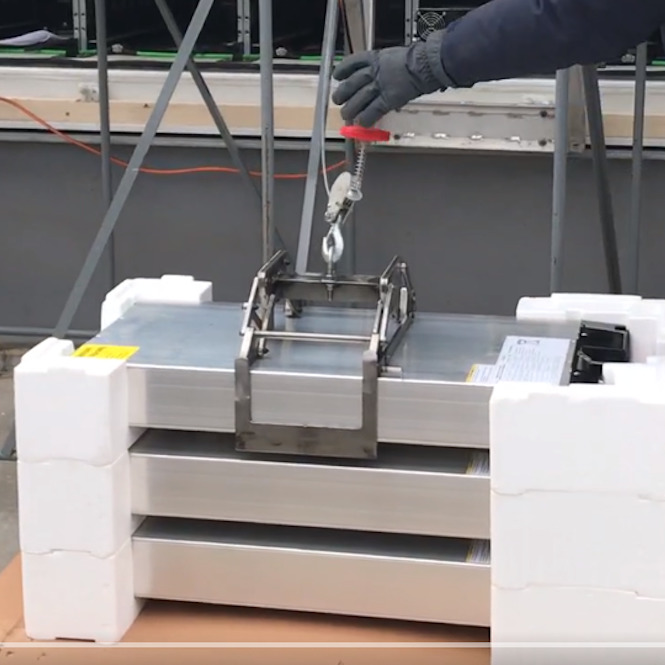

Custom Battery Loading Tools

Project Overview

Battery energy storage systems (BESS) are used to enhance the existing grid and are a key enabling technology for the renewables industry. Over the next decade, many gigawatts of storage capacity will be brought online. New methods, procedures, and tools will be needed to safely install the batteries.

It is common for a 40-ft containerized BESS to hold upwards of 350 lithium-ion battery modules, weighing more than 150 lbs. each. Large sites can have dozens of containers, while building-based solutions have aisles of racks that hold thousands of batteries. Lithium-ion technology presents significant hazards and battery modules must be handled with care. Safe, repeatable, efficient, and sustainable battery loading solutions must be developed to protect the people and property involved with this work.

CHALLENGE

IPD needed to develop tools that fit within very specific requirements. No tool could weigh more than 100 lbs. so that it could be lifted by two people. The tools needed to be compatible with any terrain or container elevation. And each of the preferred battery OEMs had different packaging, size, weight, and lift requirements for modules.

SOLUTION

IPD leveraged our rare combination of engineering, battery storage, and field service expertise to design, fabricate, test, certify, and deploy custom, battery loading tool solutions for a global BESS integration leader. The goal was to provide standard tools and methods for use across their entire portfolio of containerized products. IPD led a cross-functional team to develop and model tool concepts, including 3D printing prototypes to test and approve. All items were designed, tested and documented in accordance with ASME B30.17, ASME B30.20 and ASME BTH-1.

RESULT

IPD solved a unique and critical problem that the client faced on every installation. IPD field professionals worked with the client team to create and document the methods, procedures and training materials needed to safely and properly use the tools and load batteries. In addition to providing a safer and more repeatable solution, we were able to reduce battery loading time by upwards of 50% - this will deliver significant cost and schedule reductions.

More case studies

Click to view more examples of IPD's work: